No I'm not talking about the dance move, although I must confess it's a great move. What I am talking about is shimming an R200 VLSD. I'm sure some of you, more like most of you, have heard of shimming a diff. I had always heard of it but never really looked into doing it since I didn't have a vlsd, also I was always rather skeptical of this idea since I've never heard anything good about the vlsds.

Well, turns out I proved myself wrong...I guess I shouldn't say wrong since I never said it doesn't work, I just didn't think it would work as well as people claimed.

Just about a week ago Becca and I decided to try out drifting in the Z since we hadn't done it yet. It didn't go so well, the factory diff in the non turbo is an R200 vlsd, more in particular a very incredibly worn out one. Because of this it made doing donuts incredibly difficult to almost impossible. The diff wouldn't lock at all so it was one legging all about the place. This of course was a problem, there was no way Becca was going to be able to drift this thing at events and Proving Grounds (which is planned as her debut event) is only a month away. First idea that popped in my head was put a welded diff in it, only now we had axle length issues that would need to be solved since I've never heard of anyone swapping a welded S13 diff in a Z32. While trying to figure that out, the idea of shimming it came to mind. I figured, "why not look this up, and see what all the hype is about". That's when I discovered just how easy it is too do, and how incredibly cheap it is as well!

First thing first. I needed some shims. Which I scratched my head at for a while because there are a lot of different shim thicknesses, along with this add one or add two to make it act like a 1.5 way or 2 way. Lot of info on it, but no hardcore definite answers that I was wanting. I was after a 2 way, which I've also heard people refer to it as "acts the exact same as a welded diff" because it's locked all the time. So in order to achieve that I ordered ever so slightly thicker shims then I had seen other people use. Most threads I had seen on it people were using the .80mm thick shims, I ended up opting for the 1.01mm thick shims (I don't believe going that thick was nessisary, the .8mm thick shims will do the trick and make it easier on you to reassemble the diff as well, just a heads up for everyone.)

Here are the part numbers (Nissan calls them Thrust Washers) they are the same #'s for all R200 vlsd

.8mm thick is 38424-40F60

1.01mm thick is 38424-40F67

Once the shims arrived I set to work. This I won't go too in depth with because it's very straight forward and you can look up videos on how to do this part or even figure it out on your own. We put the Z in the garage, jacked her up, and dropped the diff.

Here you can see the diff with the back cover removed.

Make sure when you pull the diff out that you keep the spacers on both sides in order, they will need to go back in the exact same spots when you put it back together.

Now you'll pop the center section out, right away so you don't forget to do this put the longer half shaft back in the diff ALL THE WAY, you might have to turn it slightly to get the inside splines to line up so it'll go in all the way. Once you've done that you'll take off the ring gear, then remove the 2 phillips head screws. After that's done take off the vlsd cover, right away you will see where you will install the shims, from the factory there will already be a shim in place. Leave that one there and don't remove it. What you'll then do is add the 2 shims you ordered.

After you put those on you'll put the cover back on and you'll notice that there is now a gap between the cover and main housing, you won't put the phillips screws back on because you can't so don't waste your time trying. Simply put your ring gear back on. This part you will need an impact for, or super human strength. Tightening the ring gear on will seal up the cover which in part will force the VLSD together. Make sure you get this all the way tightened! After that, pull the halfshaft back out, reinstall the diff into the housing along with the spacers in the same order you removed them, be careful not to damage your spacers or bearings when doing this. It will require a small amount of force (same amount it took to get the diff out). After that bolt it back together, put the new cover gasket on, or use RTV which is what I do and almost everyone else I know of does and put her back in the car.

My first impressions after having completed this were mind blowing. I must say I was not prepared for how well it was going to work. It's going to make some noise and when you turn the tires chirp like a bird in a tree. Exactly like a welded diff. That's right, from skeptic to believer. I'm convinced, this is just as good as welding a diff and will cost you less given you already have a VLSD and the 5 bolt axles to match.

To really put this to the test we drove it around for a couple days, put some miles on her, then did some drifting. The next day tried it out again and for everyone to see I brought the camera along to get some video footage. Unfortunately blogger has been having issues finding my youtube videos lately so you'll have to click the link.

https://www.youtube.com/watch?v=M1xcp8XhVDc

Wednesday, May 29, 2013

Monday, May 20, 2013

2 Years With A 240 Named Igna

So as of the 18th it's officially been 2 years I've owned my S13. I

can't believe it's already been that long, it still feels like I just

started drifting. Anyway to celebrate my $20k investment (or whatever

I'm at now) in the car/drifting I felt some donuts were a needed thing.

Tuesday, May 7, 2013

Tow Vehicle Brake Job

Yesterday my brake parts arrived for the Sequoia. Just last week I replaced the front and yesterday I did the rear. Normally I wouldn't share something so boring, especially for my tow vehicle, except this wasn't your normal boring brake job. A rather strange discovery was made.

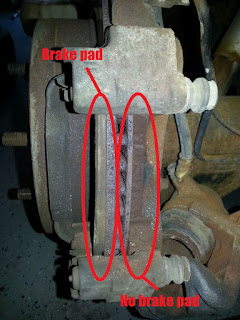

Now I knew my brakes were getting low based off the metal grinding noise that was continuously getting worse and more and more creepy, I just didn't realize they were getting this low. After removing the driverside caliper I made a discovery, one of the brake pads had gone missing. Just wasn't there, all that remained was a mangled up bit of metal that you stick on the back off the pad to reduce brake noise.

This had me confused as hell. Obviously there was a pad there at one time based off the piece you stick on the back, but where did it go? It's not like it can just pop out of the caliper and there's no way it just disintegrated because it's only been grinding for about 300 miles. I would soon find my answer, after unbolting the caliper bracket to replace my rotor I discovered some strange marks on the bracket, and when working on prying off the rotor I heard some strange metal clinging noises coming from the rotor/dust shield. It wasn't until after I removed the rotor that I discovered what happened to the pad.

Apparently the pad and the rotor had worn down so much that the pad was able to slip in between the rotor and caliper bracket, then it was caught by the dust pan. Thank God, this didn't end up destroying my caliper. The piston which was all the way pushed out hadn't come in contact with the rotor ever so I didn't have to replace that.

Here's a closer look at the worn down pad and how nasty this rotor was when I pull it off and got a good look at the backside.

After making sure everything else checked out I went ahead and slapped the new rotor on.

Then of course the new pads, and reassembled everything. Finally my brakes are fixed. Now I can comfortably put the 240 up on jack stands and begin some major work on her. Thinking I might start on this sound detaining removal.

Now I knew my brakes were getting low based off the metal grinding noise that was continuously getting worse and more and more creepy, I just didn't realize they were getting this low. After removing the driverside caliper I made a discovery, one of the brake pads had gone missing. Just wasn't there, all that remained was a mangled up bit of metal that you stick on the back off the pad to reduce brake noise.

This had me confused as hell. Obviously there was a pad there at one time based off the piece you stick on the back, but where did it go? It's not like it can just pop out of the caliper and there's no way it just disintegrated because it's only been grinding for about 300 miles. I would soon find my answer, after unbolting the caliper bracket to replace my rotor I discovered some strange marks on the bracket, and when working on prying off the rotor I heard some strange metal clinging noises coming from the rotor/dust shield. It wasn't until after I removed the rotor that I discovered what happened to the pad.

Apparently the pad and the rotor had worn down so much that the pad was able to slip in between the rotor and caliper bracket, then it was caught by the dust pan. Thank God, this didn't end up destroying my caliper. The piston which was all the way pushed out hadn't come in contact with the rotor ever so I didn't have to replace that.

Here's a closer look at the worn down pad and how nasty this rotor was when I pull it off and got a good look at the backside.

After making sure everything else checked out I went ahead and slapped the new rotor on.

Then of course the new pads, and reassembled everything. Finally my brakes are fixed. Now I can comfortably put the 240 up on jack stands and begin some major work on her. Thinking I might start on this sound detaining removal.

Monday, May 6, 2013

There's Always A Problem

My daily driving tires on my 18's have been bald for a while now, and the other day when leaving the parts store the guys convinced me a burnout was something that needed to be done, which didn't exactly help my situation. Fortunately I knew this day would come sooner or later so I already had some backup tires planned. I went out to the garage, dug through some tires and pulled out my BFG G-Forces I've had hiding in the back since last year. Whats really awesome about them is I got them for just $5 a tire!

Little did I know these tires weren't going to be the great blessing I thought they would be. I went to put them on and well...they didn't exactly fit.

I've been running a 25mm spacer on the rear, so these not fitting didn't bother me at first. I switched out the spacer for a smaller one I have. Not really sure what size it is, appears to be somewhere between 15-20mm. So I put that on and found some clearance. Just enough to fit a card in the gap.

Thinking I was good to go I left the garage and drove around a little bit. Unfortunately they rubbed, well just the one side did, my driver side had a nice mark all around the tire and the passenger side was fine with only 2 little tiny marks showing. Looks like I'm either going to have to ditch the spacer when I've got these on or pull the fender some more. I'm thinking ditch the spacer, although when I first ran these wheels without a spacer the tires rubbed on the inside by the coilovers and cut grooves in the tires. However I was running -3 degrees of camber when I did that and now I'm only running -0.5 so I think it should be fine. If not I think it'll be hammer vs quarter panel to get that extra bit of pull.

Aside from this easy to resolve tire issue, I have run into a real problem that I for some reason cannot escape, and when I bought the car I remember the previous owner telling me about this rear diff nightmare he experienced through the entire time he owned it. Apparently this is a curse and not just a nightmare like he said. Even after replacing the retainer clip inside the diff my passenger side shaft has decided to yet again pop out of the diff. I've lost count how many times this has happened now. Full of frustration I've decided it's about time I took this to an extreme. For now since I'm basically broke I ordered a new side shaft (fingers crossed this will resolve it) and as for my extreme solution I'm going to be picking up a new stock diff from my friend Rob. My plans are to weld the diff I pickup from him and keep it by my side ready to go in the car if this new side shaft pops out again. Also I'm going to start saving up for a Kaaz 1.5 LSD. This S15 HLSD just isn't cutting it.

I"m starting to get the feeling the car is intentionally causing problems with itself so I'll throw it on the jack stands and really buckle down with putting my new parts on. I think it's won my attention, I'll have the new brakes replaced on my Sequoia tonight then going to put Igna under the knife with hopes of having it back on the road before Proving Grounds on June 21st-23rd. Fingers crossed!

Little did I know these tires weren't going to be the great blessing I thought they would be. I went to put them on and well...they didn't exactly fit.

I've been running a 25mm spacer on the rear, so these not fitting didn't bother me at first. I switched out the spacer for a smaller one I have. Not really sure what size it is, appears to be somewhere between 15-20mm. So I put that on and found some clearance. Just enough to fit a card in the gap.

Thinking I was good to go I left the garage and drove around a little bit. Unfortunately they rubbed, well just the one side did, my driver side had a nice mark all around the tire and the passenger side was fine with only 2 little tiny marks showing. Looks like I'm either going to have to ditch the spacer when I've got these on or pull the fender some more. I'm thinking ditch the spacer, although when I first ran these wheels without a spacer the tires rubbed on the inside by the coilovers and cut grooves in the tires. However I was running -3 degrees of camber when I did that and now I'm only running -0.5 so I think it should be fine. If not I think it'll be hammer vs quarter panel to get that extra bit of pull.

Aside from this easy to resolve tire issue, I have run into a real problem that I for some reason cannot escape, and when I bought the car I remember the previous owner telling me about this rear diff nightmare he experienced through the entire time he owned it. Apparently this is a curse and not just a nightmare like he said. Even after replacing the retainer clip inside the diff my passenger side shaft has decided to yet again pop out of the diff. I've lost count how many times this has happened now. Full of frustration I've decided it's about time I took this to an extreme. For now since I'm basically broke I ordered a new side shaft (fingers crossed this will resolve it) and as for my extreme solution I'm going to be picking up a new stock diff from my friend Rob. My plans are to weld the diff I pickup from him and keep it by my side ready to go in the car if this new side shaft pops out again. Also I'm going to start saving up for a Kaaz 1.5 LSD. This S15 HLSD just isn't cutting it.

I"m starting to get the feeling the car is intentionally causing problems with itself so I'll throw it on the jack stands and really buckle down with putting my new parts on. I think it's won my attention, I'll have the new brakes replaced on my Sequoia tonight then going to put Igna under the knife with hopes of having it back on the road before Proving Grounds on June 21st-23rd. Fingers crossed!

Friday, May 3, 2013

Fun In The Sun

It's been a while since my last post. A good 3 weeks or so I believe. As you all know, we finished up the Z32. Had the last remaining part arrive for it the day we finished it up which was an exhaust flange for the header to exhaust. Took the car up to the exhaust shop that weekend to get something put on it. After driving it open header on the way up there both the girlfriend and myself decided maybe straight piping would be a little too loud and obnoxious, so we decided to throw a muffler on it. The shop had a nice Magniflow or Flowmasters (Can't remember which one) dual inlet/outlet muffler laying around which we got a killer deal on so we went ahead and threw that on there. Unfortunately at the time I didn't think to take any pics so all I have to show is a shot of the flange we bought and the car with the tips sticking out.

I'm really happy with the way the car sounds now. Has a nice mean rumble to it. The new clutch works amazing as well! Now Becca just needs to get some practice behind the wheel with it so she can start sliding at events!

Now on to some more recent things. It's looking like my knuckles will be shipping out any day now (fingers crossed it's for real this time) however the PBM inner tie rods are anyones guess. If the knuckles arrive I'll be in need of a longer tie rod setup. After some quick researching I found my answer. 2003-2008 Maxima inner tie rods are 13.3" long compared to my current S14 length tie rods which are 11.4" long. Right there is a difference of 2" which I'm predicting I will need. GKtech thought that with the Zero Ackerman arms I would need 20mm of length give or take. For those of you who don't know mm to inch conversions 20mm is just under an inch, .87 to be exact. The reason I went with something that's 2" is because I moved my front track out 1.5" so I'll be needing all 2" of extra length the tie rods offer.

I'm sure most of you by now have seen the commercial or know about the site, which I have a million times, but this was my first time to actually try it out. RockAuto.com, I've heard people say its great but with the commercials being so ridiculous and cheesy I always figured it was a joke. Well, i found out first hand its fucking awesome! The local parts store wanted $80 per tie rod for Moog brand inners. RockAuto had them listed for $37 a piece for the same Moog brand. So I went ahead and ordered from them. The shipping was stupid fast and it was all around a very pleasant experience. Since then I've also orderd brakes for my Sequoia and my current savings with everything I've ordered from them is at $320!

I've been out to the garage a few times, cleaning, rearranging, brought my tool box out there from home and a bunch of other crap. I'm quickly running out of room, so I devised a new way to organize my tire stash which cleared up some space. When doing that I soon realized, my stash is running low and I'm in need of some tires! Dumpster diving I went! Tires I found! Found 4 matching tires with a decent amount of tread left on them, good day for me!

Now onto the fun in the sun! Spring is here...well I think at least...It snowed these past two days and it's MAY! The record snowfall for the month of May here in Des Moines was 1.4inches. Today we beat that record with 3.4inches, and to think early this week it was 75-80 degrees which could only mean one thing. Photo Shoot!!!

Time to put Becca's new camera to the test! We drove around with the windows down all day, and snapped all sorts of photos everywhere we went. Here are just a few of my favorites! For the complete album of shots click the link for Becca's Flickr account.

Jerren was having a lot of fun all day too. Not just because he got to drive my car around, he also got to shoot at me with my ray gun keychain.

I of course then had a little too much fun during the editing process...This was the first time I've ever really used photoshop. Back in highschool I took a computer drafting class which touched base with it learning the basics but that was a good 6 years ago I did that so I really had no idea what I was doing. In the end tho I'm pretty happy with how these two turned out for me, definitely got a good laugh out of it!

I think that wraps things up for now. Funding has been preventing me from making it out to any events so far, with having missed 2 that I wanted to go to I've started buckling down on savings these past two weeks since I'm not going to miss Proving Grounds which is June 21st - 23rd! I've got about 8 weeks to get a bunch of these parts installed on the car and save my money up for the event. Hopefully I'll be doing some work on the car soon and I have pictures of the work with my next update! See you all next post!

I'm really happy with the way the car sounds now. Has a nice mean rumble to it. The new clutch works amazing as well! Now Becca just needs to get some practice behind the wheel with it so she can start sliding at events!

Now on to some more recent things. It's looking like my knuckles will be shipping out any day now (fingers crossed it's for real this time) however the PBM inner tie rods are anyones guess. If the knuckles arrive I'll be in need of a longer tie rod setup. After some quick researching I found my answer. 2003-2008 Maxima inner tie rods are 13.3" long compared to my current S14 length tie rods which are 11.4" long. Right there is a difference of 2" which I'm predicting I will need. GKtech thought that with the Zero Ackerman arms I would need 20mm of length give or take. For those of you who don't know mm to inch conversions 20mm is just under an inch, .87 to be exact. The reason I went with something that's 2" is because I moved my front track out 1.5" so I'll be needing all 2" of extra length the tie rods offer.

I'm sure most of you by now have seen the commercial or know about the site, which I have a million times, but this was my first time to actually try it out. RockAuto.com, I've heard people say its great but with the commercials being so ridiculous and cheesy I always figured it was a joke. Well, i found out first hand its fucking awesome! The local parts store wanted $80 per tie rod for Moog brand inners. RockAuto had them listed for $37 a piece for the same Moog brand. So I went ahead and ordered from them. The shipping was stupid fast and it was all around a very pleasant experience. Since then I've also orderd brakes for my Sequoia and my current savings with everything I've ordered from them is at $320!

I've been out to the garage a few times, cleaning, rearranging, brought my tool box out there from home and a bunch of other crap. I'm quickly running out of room, so I devised a new way to organize my tire stash which cleared up some space. When doing that I soon realized, my stash is running low and I'm in need of some tires! Dumpster diving I went! Tires I found! Found 4 matching tires with a decent amount of tread left on them, good day for me!

Now onto the fun in the sun! Spring is here...well I think at least...It snowed these past two days and it's MAY! The record snowfall for the month of May here in Des Moines was 1.4inches. Today we beat that record with 3.4inches, and to think early this week it was 75-80 degrees which could only mean one thing. Photo Shoot!!!

Time to put Becca's new camera to the test! We drove around with the windows down all day, and snapped all sorts of photos everywhere we went. Here are just a few of my favorites! For the complete album of shots click the link for Becca's Flickr account.

Jerren was having a lot of fun all day too. Not just because he got to drive my car around, he also got to shoot at me with my ray gun keychain.

I of course then had a little too much fun during the editing process...This was the first time I've ever really used photoshop. Back in highschool I took a computer drafting class which touched base with it learning the basics but that was a good 6 years ago I did that so I really had no idea what I was doing. In the end tho I'm pretty happy with how these two turned out for me, definitely got a good laugh out of it!

I think that wraps things up for now. Funding has been preventing me from making it out to any events so far, with having missed 2 that I wanted to go to I've started buckling down on savings these past two weeks since I'm not going to miss Proving Grounds which is June 21st - 23rd! I've got about 8 weeks to get a bunch of these parts installed on the car and save my money up for the event. Hopefully I'll be doing some work on the car soon and I have pictures of the work with my next update! See you all next post!

Subscribe to:

Posts (Atom)